Semi Tubular Rivet Manufacturer

Valley Fastener is proud to be a leading manufacturer of semi-tubular rivets in the USA. We design, manufacture, finish, & supply semi-tubular rivets for OEM manufacturers across the country.

Semi-Tubular Rivets vs Tubular Rivets

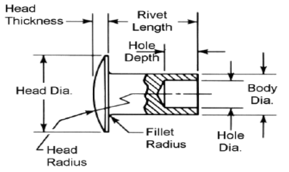

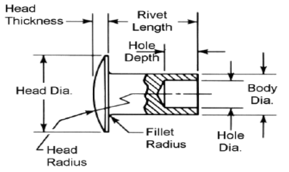

A semi-tubular rivet, also known as a hollow rivet, has a manufactured head on one end and tubular shank hole-depth less than 112% of the shank diameter.

A tubular rivet on the other hand has a tubular shank hole-depth equal to or greater than 112% of the shank diameter.

Semi-Tubular & Tubular Rivet Applications

Semi-tubular and tubular rivets are excellent fasteners to quickly and inexpensively join work-piece materials together. The tubular portion of the rivet may be fastened to a tight or loose (hinged assemblies) fit depending on the application. Riveted work-pieces are most often joined together by impacting or compressing the tubular end of the rivet with a crimping die (rivet anvil). The length of the rivet shank must be long enough to pass through work-piece with enough shank length left over for the clinching process. The tightness of the clinched joint is determined by the amount of force applied to the clinched end of the rivet and can easily be adjusted. Call Valley Fastener Group your semi tubular rivet manufacture to request a quote for your custom semi-tubular rivets!

Customization Options

Semi-Tubular Rivet Head Styles

- Oval

- Truss

- Button

- Flat

- Countersunk

Materials

- Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

Plating & Coating

Selected by end-user, dependent on application

Why use Semi-Tubular or Tubular Rivets?

- High-speed assembly. Semi-tubular rivets feed automatically in impact rivet machines that cycle in approximately 3/10th of a second. Spin/orbital methods of clinching cycle in approximately 5-8 seconds

- Can be clinched in impact rivet machines or in spin/orbital/radial style rivet machines. Air, hydraulic or mechanical presses and hand clinch tools can also be used

- Clinch force required to fasten is typically less than 40% of solid rivets so a less expensive assembly machine is required

- Permanent fastener with good joint strength

- Ease of joint inspection

- Rivet clinches can be roll-clinched, segmented (star set), spun, flared or press clinched

- Can be used to fasten similar or different materials of multiple work-pieces. Can be applied to tightly fasten joints together or used in hinged assemblies

- Tubular-hole rivets often used to pierce and clinch materials (leather-corrugated-plastic-rubber-fabric) without a pre-drilled or punched work-piece hole

- Rivets can also be used with a rivet cap to improve appearance of clinched end

- Long length rivets can be applied without buckling or bending the rivet shank

- Inexpensive alternative to threaded fasteners

- Virtually no scrap is produced during the manufacturing process

- Easily adapted for automation

| STANDARD OVAL HEAD SEMI-TUBULAR RIVET DIMENSIONS | ||||||||||

| Shank Diameter | Head Diameter | Head Thickness | Approx Head Radius | Hole Diameter | Hole Depth | Max. Fillet Radius head to shank | ||||

| Max | Min | Max | Min | Max | Min | Ref | Max | Min | Nom | |

| 0.061 | 0.058 | 0.114 | 0.104 | 0.019 | 0.015 | 0.16 | 0.044 | 0.039 | 0.046 | 0.008 |

| 0.089 | 0.085 | 0.152 | 0.142 | 0.026 | 0.02 | 0.22 | 0.068 | 0.062 | 0.064 | 0.012 |

| 0.099 | 0.095 | 0.192 | 0.182 | 0.032 | 0.026 | 0.27 | 0.076 | 0.07 | 0.077 | 0.012 |

| 0.123 | 0.118 | 0.223 | 0.213 | 0.038 | 0.03 | 0.31 | 0.09 | 0.084 | 0.094 | 0.016 |

| 0.146 | 0.141 | 0.239 | 0.229 | 0.045 | 0.035 | 0.27 | 0.107 | 0.1 | 0.126 | 0.02 |

| 0.188 | 0.182 | 0.318 | 0.306 | 0.065 | 0.055 | 0.25 | 0.141 | 0.134 | 0.155 | 0.025 |

| 0.217 | 0.21 | 0.444 | 0.43 | 0.075 | 0.061 | 0.63 | 0.163 | 0.155 | 0.189 | 0.025 |

| 0.252 | 0.244 | 0.507 | 0.493 | 0.085 | 0.071 | 0.72 | 0.184 | 0.176 | 0.219 | 0.03 |

| 0.31 | 0.302 | 0.57 | 0.554 | 0.1 | 0.086 | 0.69 | 0.219 | 0.211 | 0.243 | 0.03 |

| SEMI-TUBULAR RIVET LENGTH INCREMENTS, TOLERANCES & FILLET RADIUS | |||||

| Shank Diameter | Length Increment | Minimum Length | Length Tolerances Expressed as plus/minus | ||

| Up to and including 4 Times Shank Diameter | Over 4 Times and up to 8 Times Shank Diameter | Over 8 Times Shank Diameter | |||

| .058-.061 | 1/64 | 1/16 | 0.007 | 0.008 | 0.01 |

| .085-.089 | 1/64 | 1/16 | 0.007 | 0.008 | 0.01 |

| .095-.099 | 1/64 | 5/64 | 0.007 | 0.008 | 0.01 |

| .118-.123 | 1/64 | 3/32 | 0.007 | 0.01 | 0.015 |

| .141-.146 | 1/32 | 1/8 | 0.01 | 0.012 | 0.015 |

| .182-.188 | 1/32 | 5/32 | 0.01 | 0.012 | 0.015 |

| .210-.217 | 1/16 | 3/16 | 0.01 | 0.015 | 0.02 |

| .244-.252 | 1/16 | 7/32 | 0.01 | 0.015 | 0.02 |

| .302-.310 | 1/16 | 1/4 | 0.01 | 0.015 | 0.02 |

| SUGGESTED WORK PIECE HOLES & CLINCH ALLOWANCES | ||||

| Body Diameter | Work Hole Diameter Recommended Minimum | Clinch Allowance Max | ||

| .058-.061 | 0.063 | 0.038 | ||

| .085-.089 | 0.093 | 0.058 | ||

| .095-.099 | 0.103 | 0.065 | ||

| .118-.123 | 0.129 | 0.084 | ||

| .141-.146 | 0.154 | 0.101 | ||

| .182-.188 | 0.196 | 0.129 | ||

| .210-.217 | 0.232 | 0.15 | ||

| .244-.252 | 0.265 | 0.171 | ||

| .302-.310 | 0.325 | 0.214 | ||

Ready to start your next rivet order? If you’d like to learn more, Click here.